Shop services

At Jorgensen Tool, we pride ourselves on our ability to suit the needs of our customers. To do this, we provide services including, but not limited to, CNC Milling, CNC Turning, Manual Machining, and Quality Control.

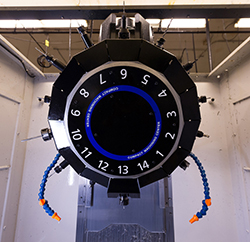

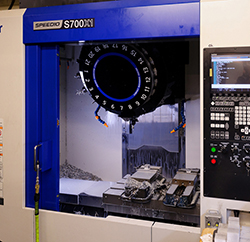

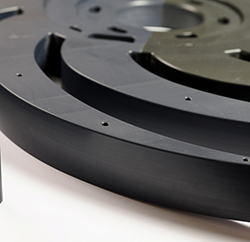

CNC Milling

Jorgensen Tool has a wide variety of CNC Machining Centers. From our high-speed RoboDrills with pallet changers to our larger, 50"x24"x24" work envelope, Doosan MV-5025, Jorgensen Tool is equipped for your jobs, production and quality requirements.

CNC Turning

We also have numerous CNC Turning Centers to fit requirements for turned components including our new Doosan Lynx 220LSY. It's twin spindles allow us to part your component from the bar, transfer it to the other spindle and complete the part, all without manual intervention.

Laser Engraving

In addition to the standard machining that makes up a machine shop, Jorgensen Tool has recently invested in a Boss LS1416 Laser Engraver. With this we can not only machine your parts, but also add laser engraved details such as a part number or description. Skip the middle man and let us bring your parts from start to finish.

Manual Machining

In order to handle requirements for single pieces and very small lots, we maintain a number of milling machines and lathes with computerized control stystems. In addition, we have drill presses, grinders, and most other types of equiment found in a modern machine shop.

Quality Control

Whether you need a second opinion or just a faster turn around than your own Quality Control Department can provide, our CMM, MicroView, and Optical Comparators are prepared to ensure that you receive the best quality products.

Jorgensen Tool has a wide variety of CNC Machining Centers. From our high-speed RoboDrills with pallet changers to our larger, 50"x24"x24" work envelope, Doosan MV-5025, Jorgensen Tool is equipped for your jobs, production and quality requirements.

CNC Turning

We also have numerous CNC Turning Centers to fit requirements for turned components including our new Doosan Lynx 220LSY. It's twin spindles allow us to part your component from the bar, transfer it to the other spindle and complete the part, all without manual intervention.

Laser Engraving

In addition to the standard machining that makes up a machine shop, Jorgensen Tool has recently invested in a Boss LS1416 Laser Engraver. With this we can not only machine your parts, but also add laser engraved details such as a part number or description. Skip the middle man and let us bring your parts from start to finish.

Manual Machining

In order to handle requirements for single pieces and very small lots, we maintain a number of milling machines and lathes with computerized control stystems. In addition, we have drill presses, grinders, and most other types of equiment found in a modern machine shop.

Quality Control

Whether you need a second opinion or just a faster turn around than your own Quality Control Department can provide, our CMM, MicroView, and Optical Comparators are prepared to ensure that you receive the best quality products.